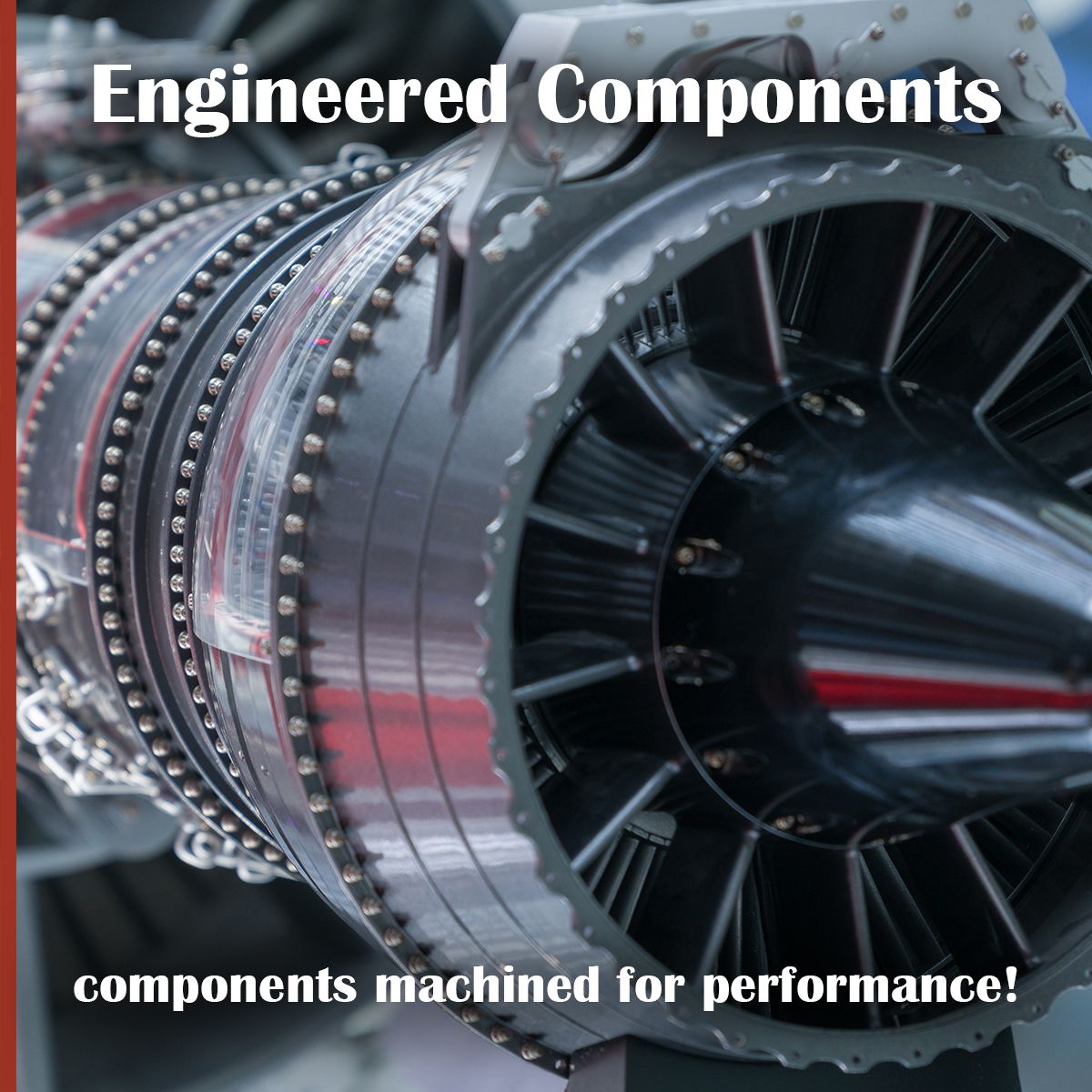

Machining plays a vital role in producing precision-engineered aerospace components, ensuring accuracy and reliability in critical applications. Through advanced methods such as CNC milling, turning, and grinding, components like turbine blades, engine housings, landing gear parts, and structural frames are manufactured from high-performance materials including titanium, aluminum alloys, and composites. These processes deliver tight tolerances, smooth finishes, and complex geometries—qualities essential for the safety, performance, and durability of aerospace systems. Each part must also comply with strict industry standards for strength, weight, and longevity.

For more information, contact RPM’s Meagan Hayden at [email protected].

#Machining #Turning #Milling #Lathe