Our History

A Legacy of Precision and Dedication

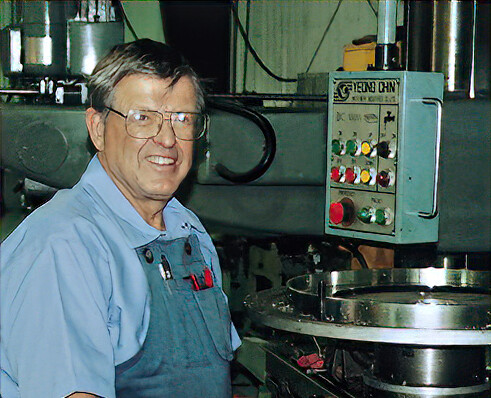

Reed’s Precision Machine (RPM) was founded in 1968 by Reed Bindrup, an accomplished machinist who saw a critical need for a reliable machine shop in Logan, Utah. Starting with just a manual mill and lathe, Reed laid the foundation of what would become a cornerstone in the local manufacturing industry. Through years of hard work, innovation, and an unyielding commitment to customer satisfaction, RPM has evolved from a small shop into a full-capacity parts manufacturing facility.

Today, with over 30,000 square feet of floor space and a dedicated team of about 38 skilled employees, we continue to uphold Reed’s vision. As we embrace the future, we are guided by the principles that have defined our past: precision, reliability, and a customer-centric approach.

Certifications and Technology

Commitment to Quality and Innovation

At Reed’s Precision Machine, we understand that quality is non-negotiable. Our commitment to excellence is reflected in our certifications and the advanced technology we employ. We are ensuring that our processes meet the stringent requirements of the aerospace industry. Our use of Mastercam, Solidworks, and other CAD systems enables us to deliver high-precision parts and components.

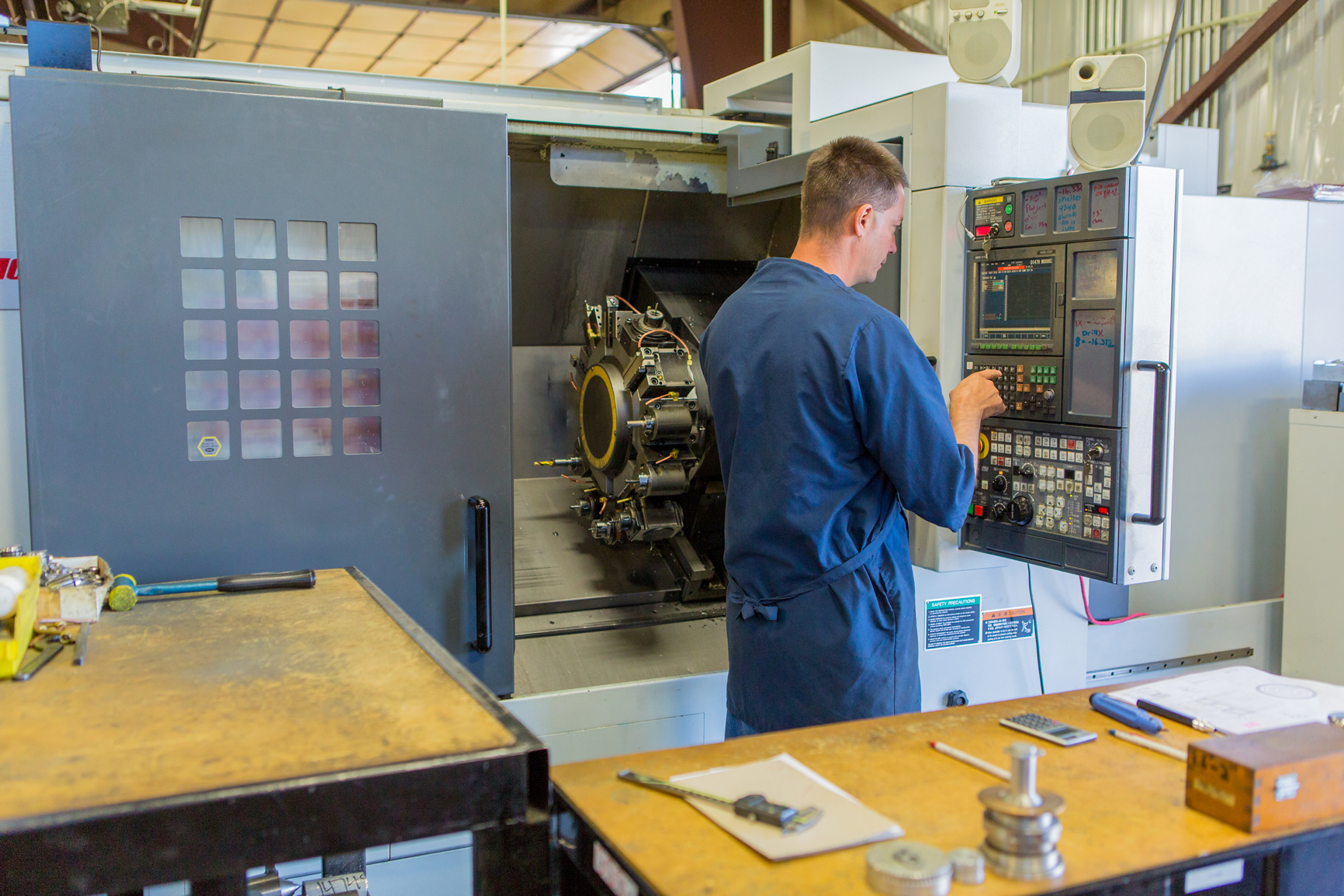

Advanced Capabilities

Our facility is equipped with state-of-the-art machinery, including CNC mills and lathes, saws, and laser etching equipment. We utilize MCOSMOS CMM software for precise measurements and quality control, and JobBOSS for efficient job management. This integration of advanced tools and software allows us to handle a wide range of projects, from simple prototypes to complex, high-tolerance production runs.

Our Services

Comprehensive Machining Solutions

Reed’s Precision Machine offers a full spectrum of machining services, designed to meet the diverse needs of our clients. Whether you require milling, lathe work, sawing, welding, or laser etching, we have the expertise and equipment to deliver exceptional results.

Flexibility and Customization

Our capabilities extend to manufacturing parts of various sizes and complexities. From tiny components less than an inch in size to large plates and hubs, we handle projects of all scales. We specialize in producing both basic and high-tolerance parts, catering to prototypes as well as high-production runs. Our flexibility ensures that we can meet the unique requirements of each project, delivering quality parts at a fair price.

Material Handling and Certification

We maintain a wide variety of materials on hand, complete with material tracking and certifications. This ensures that we can quickly respond to customer needs while maintaining the highest standards of quality and compliance.

Our Commitment

Customer-Centric Approach

At Reed’s Precision Machine, our customers are at the heart of everything we do. Unlike shops with proprietary products, we focus solely on our customers’ projects, ensuring that there is no conflict of interest. Our customers trust us with their time and materials because they know we are fair, reliable, and dedicated to their success.

Skilled Machinists and Leadership

The team at RPM are seasoned machinists who understand the intricacies of the trade. Their hands-on experience and knowledge drive our commitment to quality and efficiency. What began 50+ years ago as a family-owned business RPM has always taken pride in our legacy and is committed to passing on our values and expertise to future generations.

Packaging and Shipping

Ensuring Safe and Timely Delivery

We understand the importance of delivering parts in perfect condition and on time. Our packaging and shipping processes are designed to ensure that your parts arrive safely and promptly, ready for immediate use in your operations.