Your Partner in Semiconductor Manufacturing and Maintenance

At Reed’s Precision Machine, we understand the critical role that semiconductors play in today’s technology-driven world. Whether it’s in government or civilian applications, our machine shop offers comprehensive services tailored to the design, maintenance, manufacture, repair, and use of semiconductor components. With a legacy of nearly 50 years in the industry, we combine technical expertise with state-of-the-art equipment to deliver precision and reliability in every project.

Expert CNC Machining Services for Semiconductors

Our CNC turning services are equipped to handle the intricate demands of semiconductor manufacturing. Utilizing advanced equipment such as the MORISEIKI NLX-2500/700 Twin Spindle with live tooling and the MAZAK Quick Turn series, we can produce highly precise and complex components. These machines ensure consistency and accuracy, which are paramount in the semiconductor industry.

For example, the MORISEIKI NLX-2500/700 is used to create detailed components with tight tolerances, essential for the assembly of semiconductor devices. This equipment allows us to work with a variety of materials, ensuring the durability and performance of your semiconductor parts.

Our CNC milling services are another cornerstone of our semiconductor manufacturing capabilities. With machines like the MAZAK VARIAXIS 500-5XII, a 5-axis pallet machine, and the HAAS VF-8 Machining Centers, we can handle complex geometries and large production runs. These machines provide the precision needed to fabricate parts that meet the stringent standards of the semiconductor industry.

For instance, the MAZAK VARIAXIS 500-5XII is ideal for producing multi-faceted components that require machining on several planes. This capability is crucial for the creation of semiconductor housings and other intricate parts.

Our TYMA ZETALASE™ laser etching system is perfect for adding final touches to semiconductor components. Laser etching can be used to mark serial numbers, logos, and other critical information on parts. This process works on a variety of materials including steel, aluminum, and coated surfaces, ensuring traceability and compliance with industry standards.

We offer comprehensive welding services, including MIG, TIG, GAS, and ARC welding. These welding techniques are essential for the assembly and repair of semiconductor equipment, ensuring strong and reliable joints. Our certified welders have extensive experience in working with the delicate and precise requirements of semiconductor manufacturing.

At Reed’s Precision Machine, we pride ourselves on our ability to fabricate both metal and plastic parts with high precision. Our facility is equipped to produce specialty, high-performance parts with precise tolerance details. Whether you need custom prototypes or high-volume production runs, our parts fabrication services are designed to meet the specific needs of the semiconductor industry.

Why Choose Reed’s Precision Machine?

Reed’s Precision Machine has a rich history of serving diverse industries with unparalleled dedication and expertise. Here’s why our clients trust us:

- Comprehensive Capabilities: From milling and turning to welding and laser etching, we offer a full range of services under one roof.

- Advanced Equipment: Our state-of-the-art machinery ensures precision and efficiency in every project.

- Expert Team: Our team of skilled machinists and engineers bring decades of experience to every job, ensuring high-quality results.

- Customer-Centric Approach: We focus entirely on our customers’ needs, offering customized solutions and maintaining transparency throughout the process.

- Legacy of Excellence: With nearly 50 years in the industry, we have built a reputation for reliability and quality that our clients can depend on.

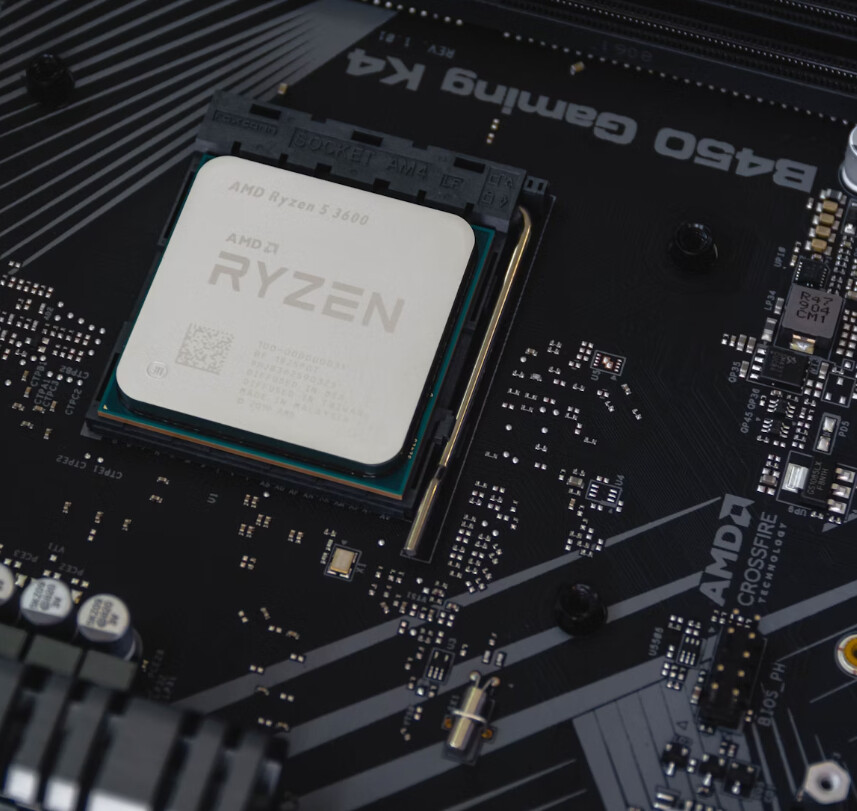

Applications in the Semiconductor Industry

Our services are designed to meet the varied demands of the semiconductor industry, including:

- Manufacturing Equipment: Precision components for semiconductor fabrication equipment.

- Repair and Maintenance: Reliable repair and maintenance services to ensure minimal downtime.

- Custom Components: Tailored solutions for unique semiconductor applications.

- Traceability and Compliance: Ensuring all parts and materials meet industry standards for quality and traceability.