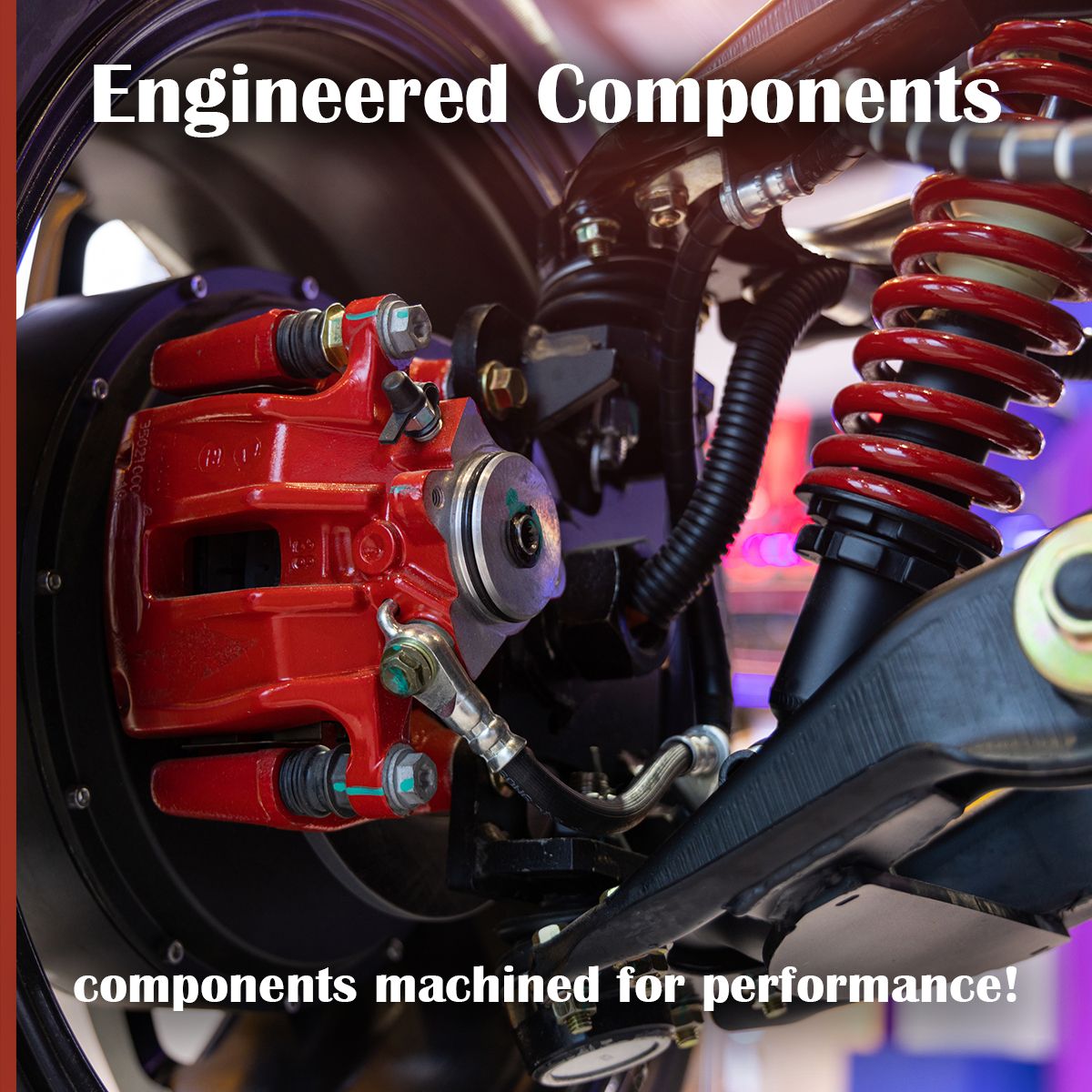

At Reed’s Precision Machine (RPM), precision-machined components play a vital role in the safety and performance of amusement park rides. Utilizing advanced CNC machining techniques—including milling, turning, and grinding—RPM manufactures critical parts such as axles, gears, hubs, bearings, and structural support frames from high-strength steels and specialty alloys. These components are engineered to meet exacting tolerances, ensuring they can withstand dynamic loads and rotational forces while maintaining reliable, smooth operation. Our focus on durability and precision helps deliver long-lasting performance and uncompromising safety.

To learn more, contact Meagan Hayden at [email protected].

#lathe #turning #machining #milling