CNC Lathe

At Reed’s Precision Machine, our CNC lathe services stand out for their precision, efficiency, and versatility. We use state-of-the-art equipment to meet industry standards, hold tight tolerances, and provide material traceability. Our CNC lathes are equipped with live tooling capabilities, enabling us to perform complex machining tasks in a single setup, thus enhancing accuracy and reducing production time.

| CNC Turning | |

| MORISEIKI NLX-2500/700 TWIN SPINDLE, LIVE TOOLING CNC Lathe and Mill | 1 |

| MORISEIKI NL-2500, LIVE TOOLING CNC Lathe and Mill | 1 |

| MAZAK QUICK TURN 10 | 2 |

| MAZAK QUICK TURN 250 HP | 3 |

| MAZAK NEXUS FUSION QUICK TURN 250 HP | 1 |

| MAZAK QUICK TURN 25L 12” dia X 48” long | 1 |

| MAZAK QUICK TURN 18N, WITH BIG BORE | 1 |

| 1 HARDINGE CONQUEST TWIN SPINDLE Live Tooling, Bar Feed | 1 |

| Manual Lathes | |

| MORISEIKI LATHES | 5 |

| MORISEIKI LATHE MH 2000G 30”X 90”, Large Capacity | 1 |

Equipment and Tooling for CNC Lathe Services

Our extensive range of CNC lathe equipment includes:

- MORI SEIKI NLX-2500/700 Twin Spindle, Live Tooling: This machine allows for simultaneous machining on both spindles, enhancing productivity and precision. The live tooling feature enables milling, drilling, and tapping operations within the same setup.

- MAZAK Quick Turn Series (10, 250 HP, 25L, 18N): These versatile lathes handle a wide range of turning applications, from simple parts to complex geometries. The Quick Turn 18N, with its big bore, is perfect for large diameter workpieces.

- HARDINGE CONQUEST Twin Spindle, Live Tooling, Bar Feed: Ideal for high-speed production, this machine’s twin spindles and bar feed system ensure continuous operation with minimal downtime.

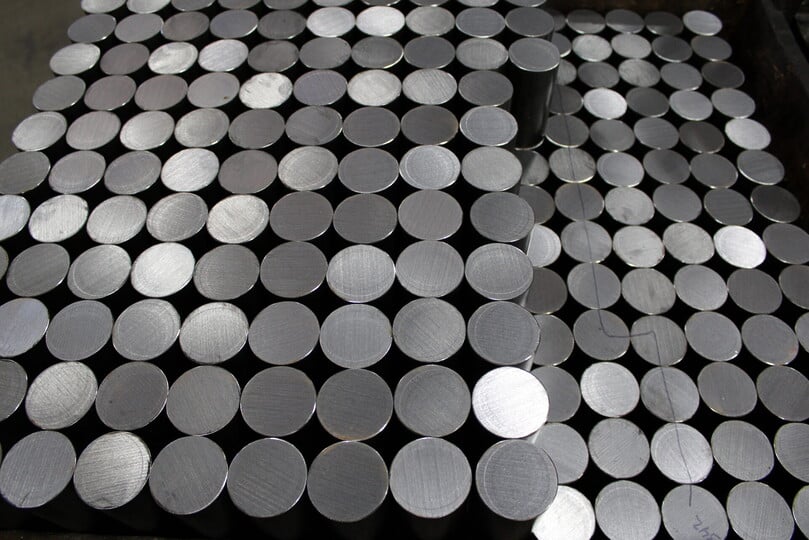

Applications and Examples

Our CNC lathe services cater to a diverse range of industries. For example, we frequently produce precision components for the aerospace sector, such as turbine blades and aircraft fasteners, requiring tight tolerances and exceptional surface finishes. In the automotive industry, we manufacture high-performance engine parts and transmission components, emphasizing durability and precision.

One-and-Done CNC Lathe Work

One of the standout features of our CNC lathe services is our “one-and-done” approach. By handling parts in a single machine setup, we achieve higher precision, faster turnaround times, and reduced costs. This method is particularly beneficial for producing complex parts that require multiple operations, such as intricate medical device components or detailed industrial machinery parts.

Gallery

“CNC lathe work of the highest quality.

Tight tolerances. Fast delivery.”