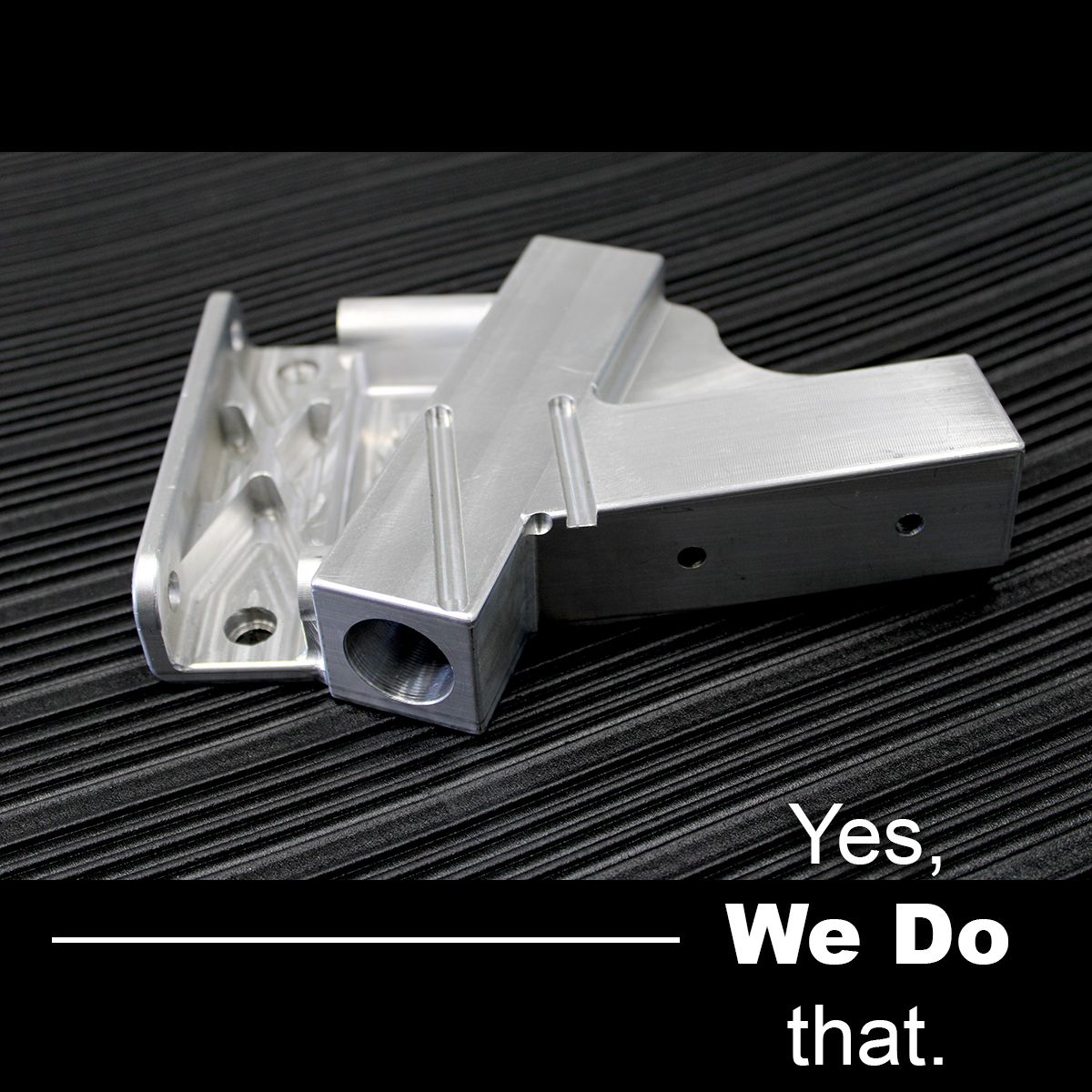

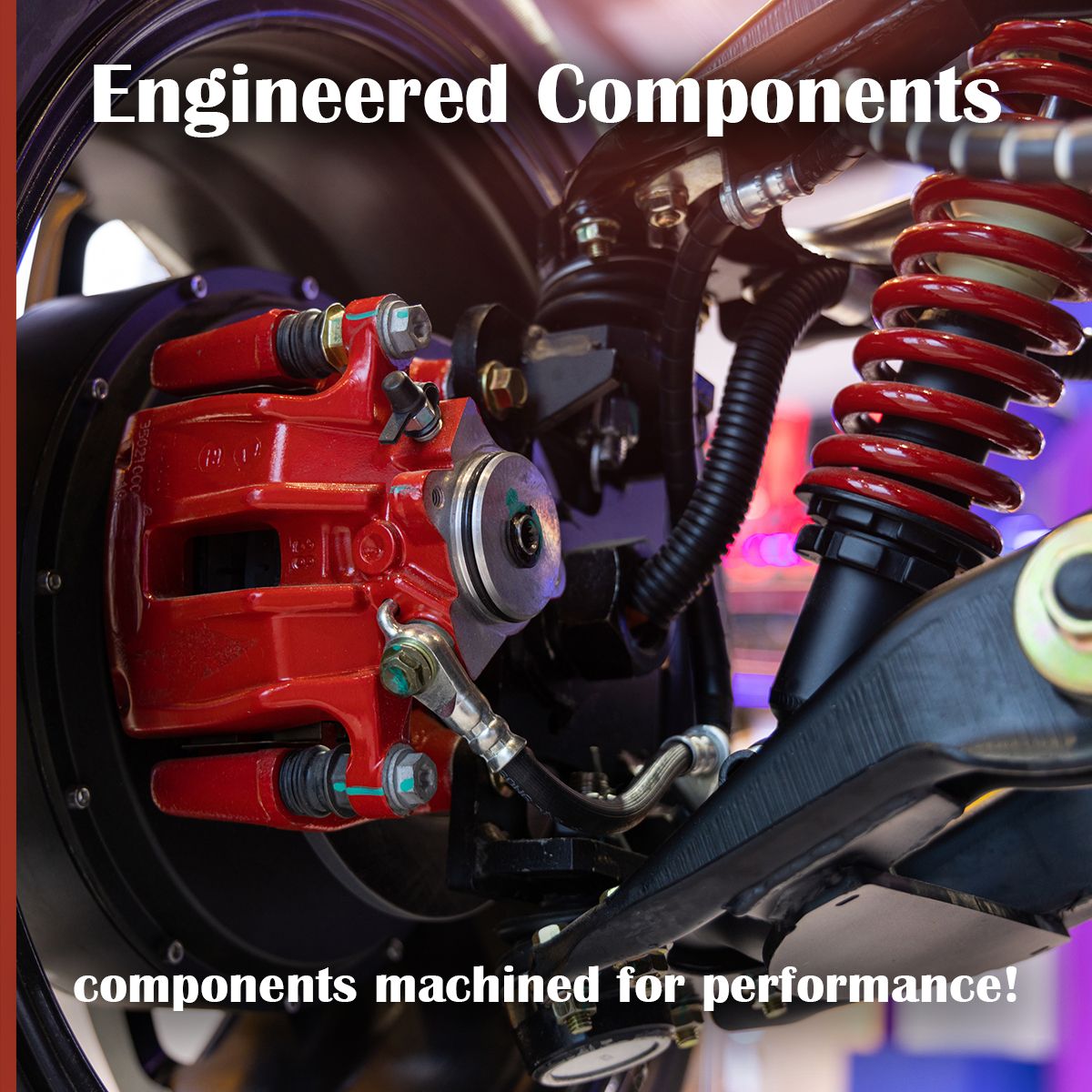

Machining plays a critical role in the manufacturing of agricultural equipment, delivering the precision and durability required for demanding field applications. Through advanced CNC milling, turning, and drilling techniques, essential components such as gears, shafts, and cutting blades are produced from high-strength steel and specialty alloys. These parts are engineered to endure continuous heavy-duty operation and exposure to harsh environments. Precision machining ensures that agricultural machinery—including plows, harvesters, and tractors—operates with exceptional reliability, efficiency, and longevity, ultimately enhancing productivity and overall equipment performance.

For more information, contact Meagan Hayden at [email protected].

#Milling #Lathe #Turning #MachinedParts #Manufacturing