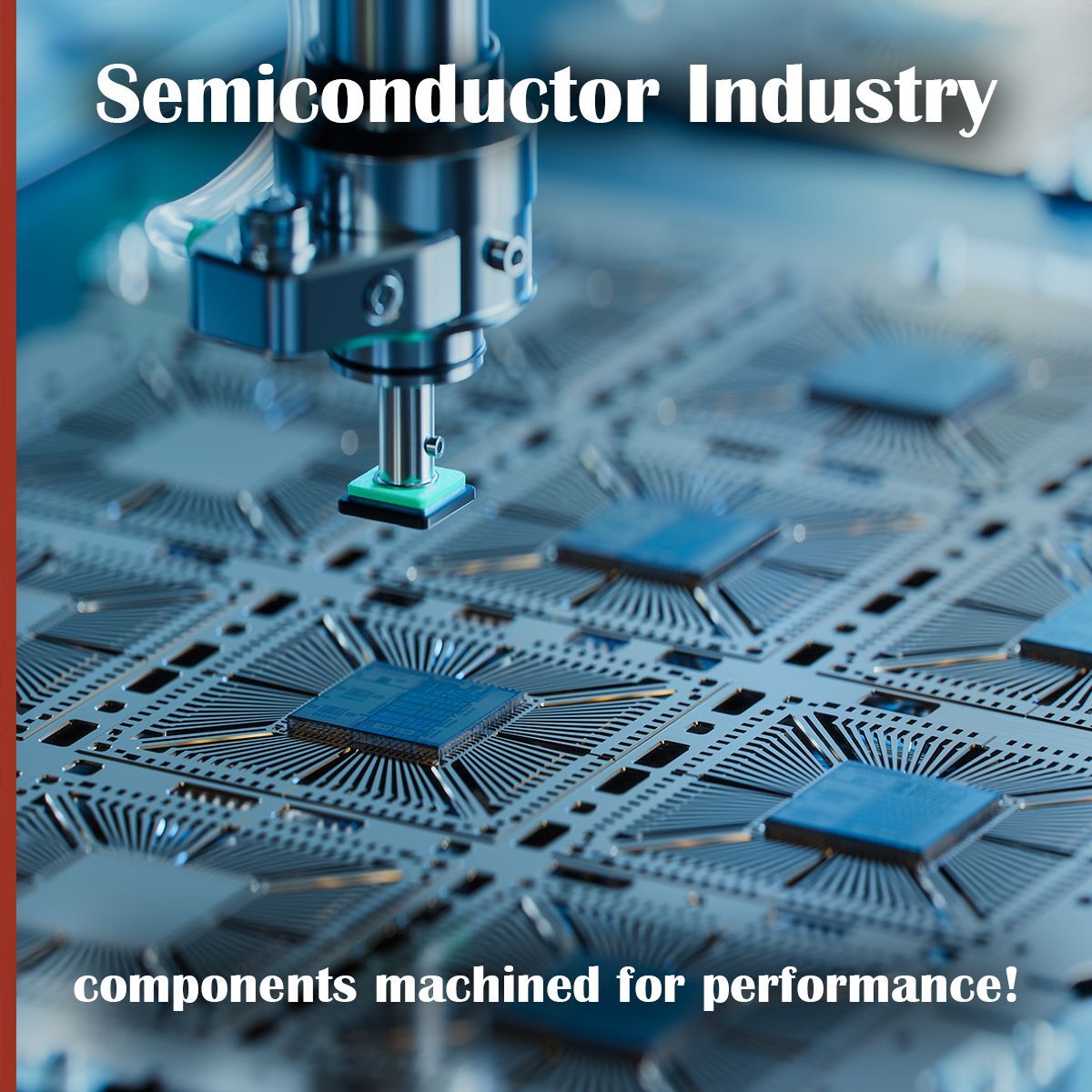

Machining is essential in the semiconductor industry, producing precision components critical to manufacturing processes. CNC milling, turning, and grinding are employed to fabricate parts such as wafer handling systems, robotic arms, alignment fixtures, and precision tooling. These components are crafted from materials like stainless steel, titanium, and specialized alloys, providing the strength and durability required for delicate operations. Precision machining ensures tight tolerances, smooth surface finishes, and accurate geometries—key for the reliable handling and processing of semiconductor wafers, ultimately supporting efficient production.

Contact RPM’s Meagan Hayden to learn more.

#CNCmilling #Turning #Machining