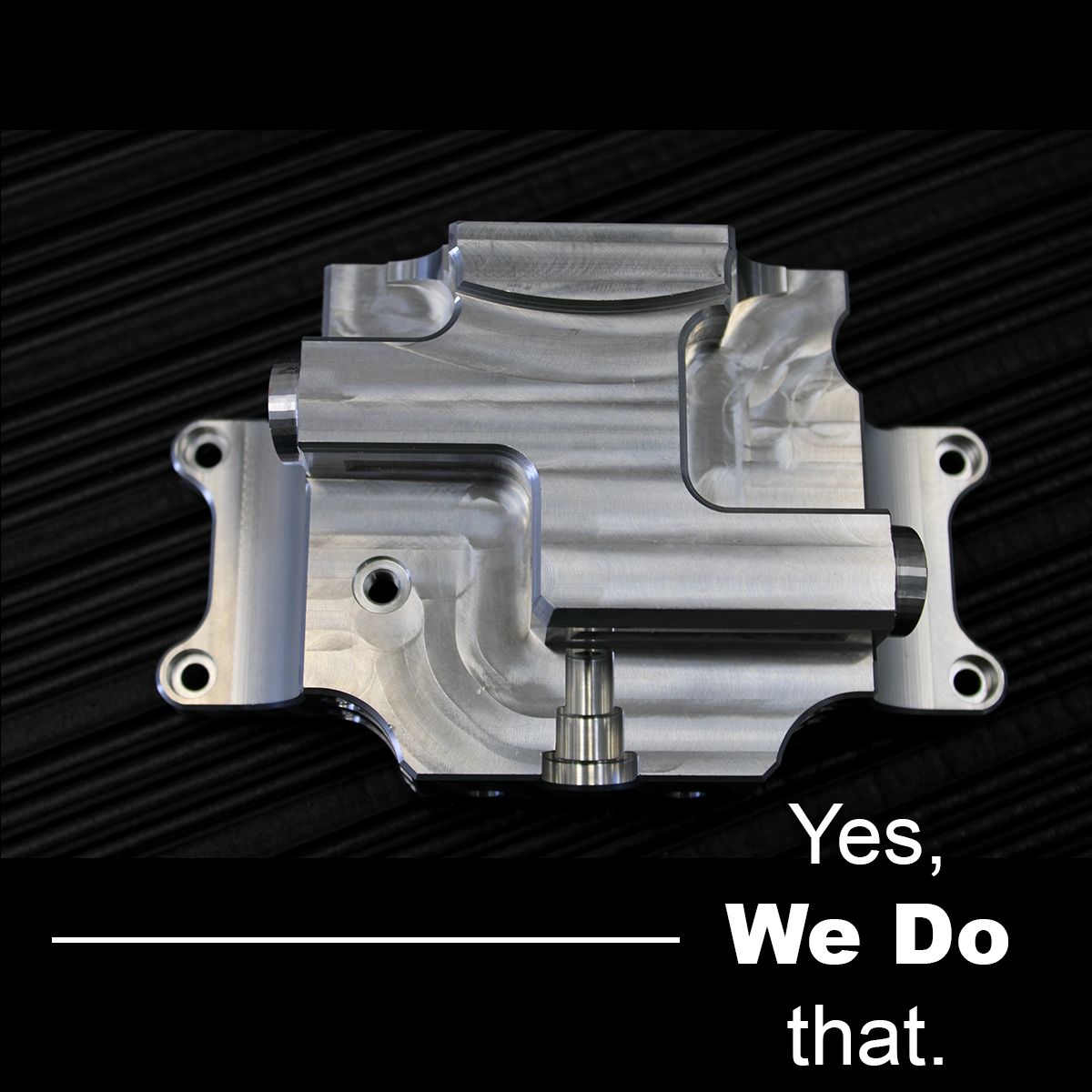

Precision-machined components play a vital role in the performance, durability, and reliability of automotive engines. Critical parts such as engine blocks, crankshafts, pistons, camshafts, valves, and cylinder heads are manufactured using advanced CNC milling, turning, and grinding techniques. These components are typically made from high-strength materials like steel, aluminum, and specialty alloys to endure extreme temperatures, pressures, and operational stresses.

Through precision machining, each part meets tight tolerances to ensure optimal fit, smooth operation, and maximum engine efficiency. The result is improved power output, fuel performance, and extended engine life.

For more information, contact Meagan Hayden at [email protected].

#AutomotiveManufacturing #Milling #Turning #Machining #MachineShop