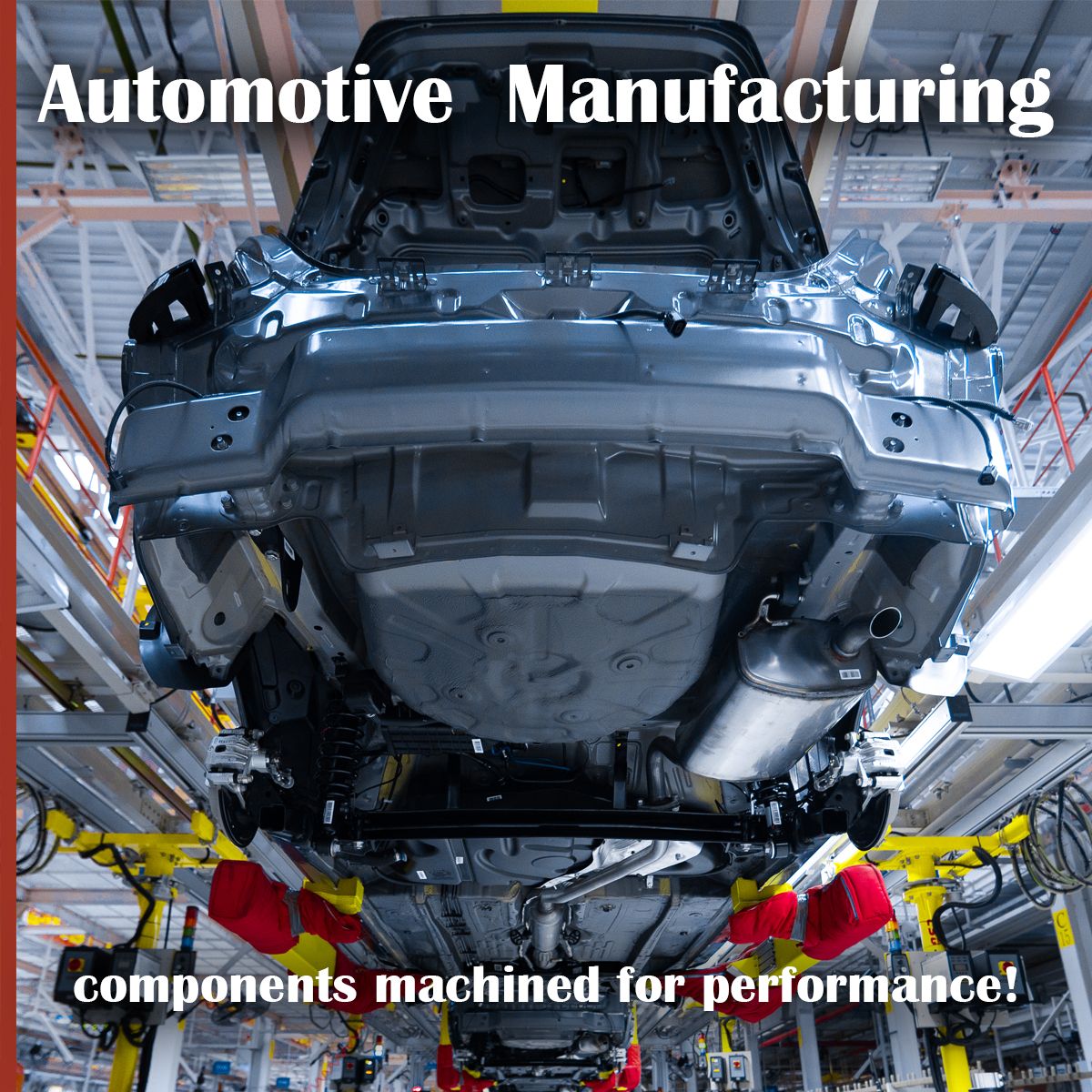

Manufacturing the automotive undercarriage requires precision and durability to ensure optimal vehicle performance and structural integrity. Essential components—such as suspension arms, chassis frames, crossmembers, and brackets—are produced using advanced machining methods including CNC milling, turning, and welding.

These parts are commonly made from high-strength steel or specialty alloys designed to endure heavy loads, impacts, and continuous stress. Precision machining guarantees tight tolerances, ensuring each component fits correctly and functions as intended. The result is improved handling, vehicle stability, and long-term durability—especially under demanding road conditions.

To learn more, contact Meagan Hayden at [email protected] or visit https://reedsprecision.com.

#Machining #CNCmilling #Turning #Lathe #Milling