Expert Services for Processing Equipment

Reed’s Precision Machine (RPM) stands as a cornerstone in the food processing industry, offering unparalleled expertise in the design, maintenance, manufacture, repair, and customization of food processing equipment. With nearly five decades of experience, our commitment to precision, quality, and customer satisfaction has earned us a trusted reputation among clients who demand the highest standards.

Comprehensive Services for Food Processing Equipment

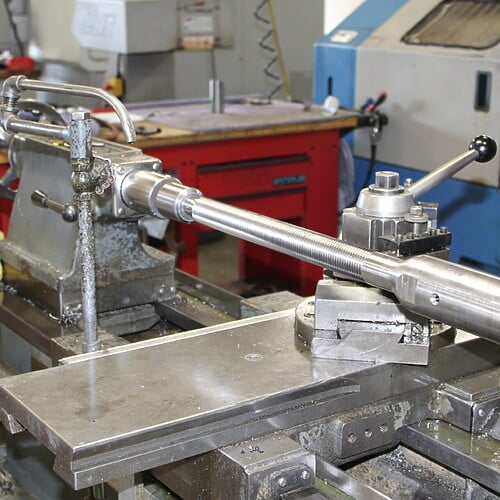

Our advanced CNC milling and turning capabilities ensure that every component of your food processing equipment is crafted with precision. Utilizing state-of-the-art equipment such as the MAZAK VARIAXIS 500-5XII and the MORISEIKI NLX-2500/700 Twin Spindle, we can handle complex geometries and tight tolerances, essential for the efficient operation of food processing machinery.

Example Application: CNC milling and turning are crucial for manufacturing intricate parts such as augers, conveyors, and cutting blades used in food processing. These parts must meet stringent sanitary standards, and our precision machining ensures they are both effective and easy to clean.

Reed’s Precision Machine offers comprehensive welding services, including MIG, TIG, GAS, and ARC welding. Our certified welders are adept at working with various materials commonly used in food processing equipment, such as stainless steel and aluminum, ensuring strong, sanitary welds that comply with industry standards.

Example Application: Our welding services are vital for constructing robust frames and support structures for food processing equipment, ensuring durability and safety in demanding environments.

With our TYMA ZETALASE™ laser etching technology, we provide precise and durable markings on a wide range of materials. This service is essential for etching serial numbers, logos, and other identification marks on food processing equipment, facilitating traceability and compliance with regulatory requirements.

Example Application: Laser etching is used to mark stainless steel components with part numbers and manufacturer information, ensuring traceability and adherence to food safety regulations.

Our parts fabrication services cater to both metal and plastic components, offering customized solutions tailored to the unique needs of food processing equipment manufacturers. From high-performance plastic parts to precision metal components, we deliver products that meet the highest industry standards.

Example Application: Fabrication of custom nozzles, valves, and fittings that are essential for maintaining hygiene and efficiency in food processing systems.

Equipped with cutting-edge machinery like the Bundle Saw AMADA Automatic Feed and the DYNASAW 430, our saw shop provides precise cutting services for various materials. This capability is crucial for preparing raw materials that will be further machined or assembled into food processing equipment.

Example Application: Accurate cutting of stainless steel sheets and bars used in the construction of hoppers and chutes for food processing lines.

Our rigorous material traceability system ensures that all materials used in your projects are tracked from source to final product. This system provides assurance of quality and compliance, which is critical in the food processing industry where material certification is mandatory.

Expertise and Experience

With nearly 50 years of experience, Reed’s Precision Machine combines traditional craftsmanship with modern technology to deliver exceptional results. Our team of skilled machinists, engineers, and technicians are dedicated to meeting the specific needs of the food processing industry.

State-of-the-Art Equipment

Our facility is equipped with the latest machinery and technology, allowing us to handle a wide range of projects, from small, intricate parts to large, complex assemblies. Our investment in advanced equipment ensures that we can meet the highest standards of precision and quality.

Commitment to Quality

At RPM, quality is paramount. We adhere to strict quality control procedures and use only the finest materials to ensure that our products meet or exceed industry standards. Our commitment to quality is reflected in everything we do, from initial design to final delivery.

Customer-Centric Approach

We understand that every customer has unique requirements, and we pride ourselves on our ability to provide tailored solutions. Whether you need a one-off prototype or a high-volume production run, we work closely with you to ensure that your needs are met.

Serving Military and Civilian Applications

Reed’s Precision Machine is not only a leader in the civilian food processing industry but also serves military applications. Our precision machining capabilities are utilized in the production of equipment that must meet rigorous standards for reliability and performance.

Common Food Processing Equipment Customers

Our clientele includes leading food processing companies that require precision-engineered components and reliable maintenance services. We have established long-term relationships with these companies by consistently delivering high-quality products and services that enhance their operational efficiency and compliance with industry regulations.

Example Application: Companies that manufacture bread and bakery products rely on our precision-machined components for their dough mixers and proofing machines, ensuring consistent product quality and safety.